CUTTING EDGE APPROACH FOR STREAMLINED SOLUTIONS.

SERVICES WE PROVIDE

Repetition Engineering

J&J Engineering is a leader in repetition engineering services, specializing in the mass production of identical, high-quality parts. This process is essential for industries that require large volumes of components with strict adherence to detailed specifications. Through advanced machinery and automation, repetition machining allows for the efficient production of parts while maintaining tight tolerances and reducing the risk of variation. Whether manufacturing parts for automotive, industrial machinery, or agriculture, food and beverages, J&J Engineering’s expertise in repetition machining ensures that every piece is consistent in performance and durability. The company’s commitment to quality control and precision guarantees that even the most complex designs are replicated with exact accuracy, making J&J Engineering a trusted partner for long-run production needs.

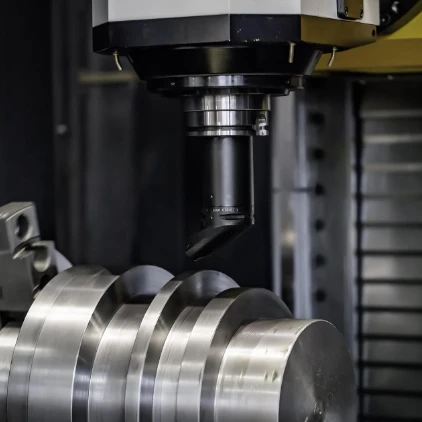

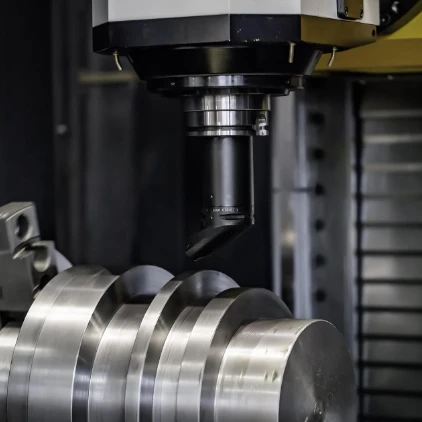

CNC Milling

J&J Engineering also excels in CNC Milling, a versatile process used to produce parts with complex shapes and intricate features. CNC Milling involves the use of computer-controlled cutting tools that move along multiple axes to precisely remove material from a stationary workpiece. This process is ideal for manufacturing parts that require detailed contours, pockets, and angular cuts. With its state-of-the-art CNC Milling equipment, J&J Engineering can create components with exceptional accuracy, meeting even the most demanding specifications. The company serves a wide range of industries where precision and quality are paramount. By leveraging the latest technology and a highly skilled team, J&J Engineering delivers milling solutions that are tailored to the unique needs of each client, ensuring that every part meets the highest standards of performance and reliability.

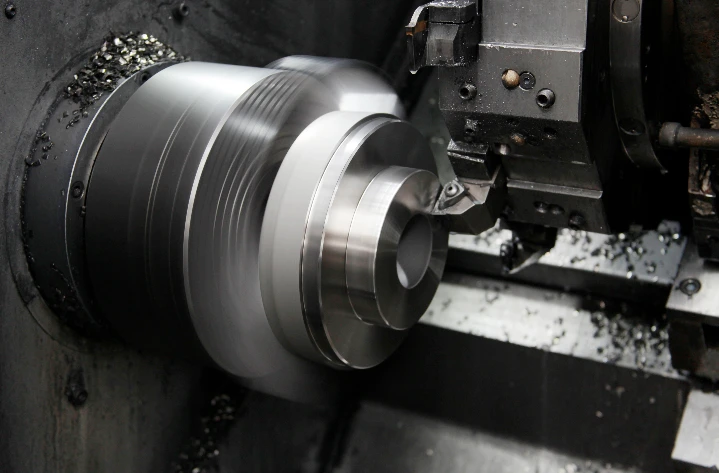

CNC Turning

In addition to its repetition machining capabilities, J&J Engineering offers CNC Turning services, an advanced process that produces cylindrical parts through the precise removal of material. CNC Turning involves securing a workpiece on a rotating spindle while cutting tools shape it into the desired form. This method is particularly effective for creating components like shafts, bolts, and other rotationally symmetrical parts. With the integration of cutting-edge CNC technology, J&J Engineering can achieve intricate geometries, exceptional surface finishes, and high levels of precision. The company’s CNC Turning services are designed to meet the specific requirements of each project, from small prototype runs to large-scale production, ensuring flexibility and adaptability for various industries. The attention to detail and technical expertise applied to CNC Turning makes J&J Engineering a go-to source for clients seeking precision-engineered solutions.

Manual Machining

At J & J Engineering , we have a team of highly skilled and experienced machine operators who can be entrusted with manual machining jobs.There are still a number of jobs where manual machining is amore viable and cost-effective solution. For jobs where the batch size is small or only one-off part may have to be made , manual machining will much more efficient and cost effective than cnc machining which will require creation of program etc.

With proper systems and processes in place , our team of highly trained and experienced personel is adept in carrying out such work with high accuracy and quality.

If you need any manual machining , reach out to us and experience quality workmanship.

APPLICATIONS WE CATER TO:

CO2

Ammonia

Chlorine

Others